A quick word about 3D printing

Although big media channel started to talk about 3D printing only few years ago, it is not a new technology. The first appearance of 3D printing technology dates back to the 1980’s. At this time, it was referred to as rapid prototyping (RP) technology [1]. In May 1980, Dr Kodama (Japan) filed the first patent on RP technologies. His technology was based on photo hardening of polymers exposed to UV. But it is not considered as the birth of 3D printing since all the pattern specifications were not filed by the deadline. In 1984, Charles Hull developed a RP technique based on stereolithography and filed the patent, which is considered as the origin of 3D printing. Other RP technologies followed stereolithography apparatus (SLA), such as selective laser sintered (SLS, 1987) and fused deposition modelling (FDM, 1989), etc. These techniques were focused on industrial applications and prototyping [2,3].

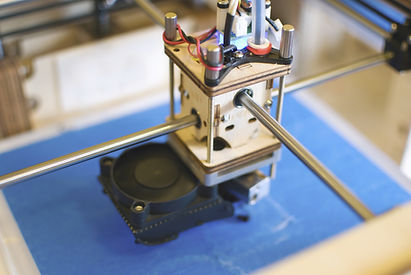

Starting from the 2000’s, 3D printing development sped up. In 2002, 3D printing reaches the regenerative medicine research thanks to the possibility of “printing” organs. In 2005, RepRap was founded. RepRap is an open-source initiative with the idea to develop a 3D printer able to print its own parts, in other words, a self-replicating printer. The on-demand manufacturing emerged in 2006 with the first viable SLS printer. The first commercially available printer was offered in 2009, it was based on the RepRap system. Ever since, the price of the 3D printers keeps falling while their accuracy keeps rising. In the meantime, many breakthroughs in 3D printing applications were performed: first prosthetic leg printed and implanted (2008), first 3D-printed blood vessel (2009), first 3D-printed and flying aircraft (2011), first 3D-printed car (2011), 3D printing of gold and silver (2012)… [2,3].

By Elisabeth

Which additive processing techniques exist today?

The additive processes can be classified depending on their raw material, as depicted below (image from [1]).

The most common and well established technologies are stereolithography (SLA), selective laser sintering (SLS) and fused deposition modeling (FDM), each using a different states of raw materials (respectively liquids, powders and filaments) [1]. Therefore, we will detail how these technologies work in further webpages. The focus will especially be put on FDM, as this is our technique of choice. To show that 3D printing is still a very new and still growing technology, we will also detail a fairly young process: Continuous Liquid Interface Production (CLIP) [4].

Bibliography

[1] Wendel, B., Rietzel, D., Kühnlein, F., Feulner, R., Hülder, G. and Schmachtenberg, E. (2008), Additive Processing of Polymers. Macromol. Mater. Eng., 293: 799–809. doi:10.1002/mame.200800121

[2] DANA GOLDBERG, History of 3D Printing: It’s Older Than You Are (That Is, If You’re Under 30), SEPTEMBER 5, 2014, https://redshift.autodesk.com/history-of-3d-printing/

[3] The Free Beginner’s Guide: 02 – History of 3D Printing, 3D Printing Industry, 2017, http://3dprintingindustry.com/3d-printing-basics-free-beginners-guide/history

[4] Wikipedia, Continus Liquid Interface Production, https://en.wikipedia.org/wiki/Continuous_Liquid_Interface_Production

By Roselien